Quality

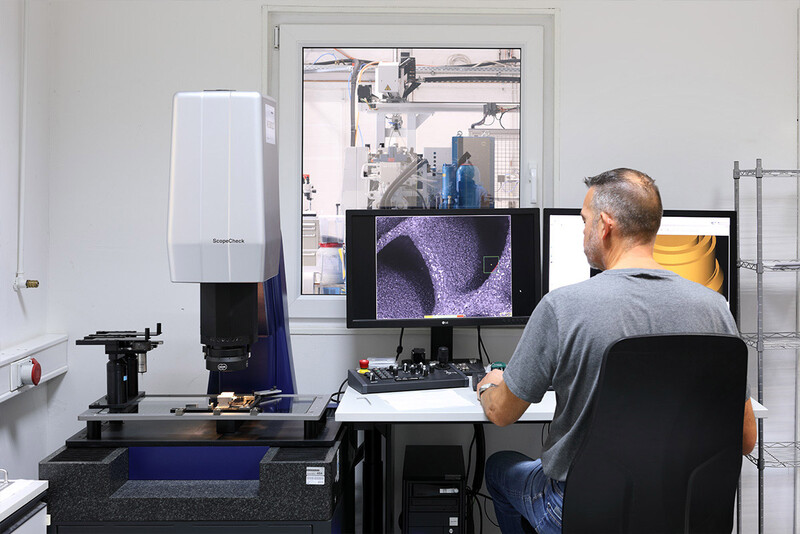

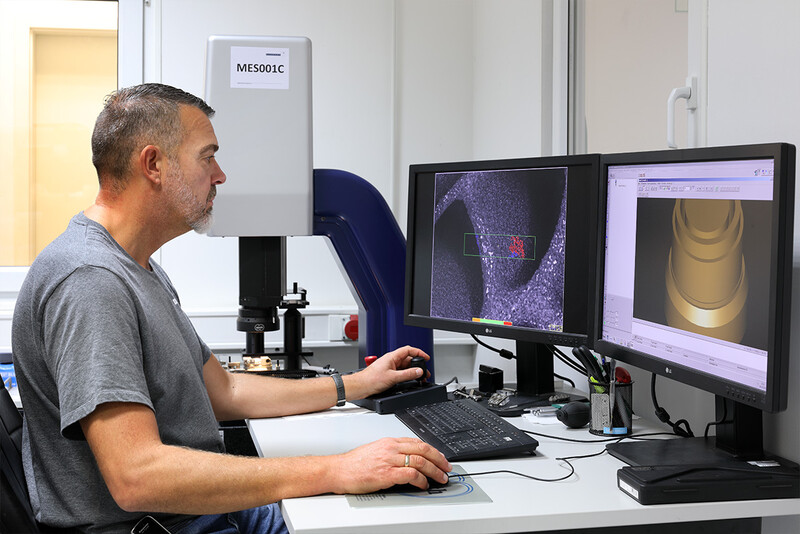

While applying disruptive technologies, Quality is the base of Element 22s manufacturing processes.

Throughout the organization, all Element22 employees are responsible for Quality. Element22’s foundation is the company culture, regulatory compliance and pursuit of best technology & production methods available to serve our customers’ needs.

Element22 has implemented quality objectives that are periodically updated in order to bring the best products and services to the market by:

- Pursuit of high-quality product that is shipped to customers on time

- Continuous improvement throughout the entire organization

- Regulatory compliance

- Continuation of international standardized certifications

Element22 GmbH has a certified quality management system according to the international standards EN 9100, EN ISO 13485 and ISO 9001. Our certificates can be downloaded below:

- ISO 9001:2015, Quality Management Systems - Requirements

english - EN ISO 13485:2016, Medical devices – Quality Management Systems – Requirements for regulatory purposes

english | german - EN 9100:2018 Quality Management Systems – Requirements for Aviation, Space and Defense Organizations

english

The implantable Titanium MIM components are approved around the globe for implantation into the human body. These parts are manufactured and certified according to the following ASTM standards:

- ASTM F2885-17: “Standard Specification for Metal Injection Molded Titanium-6Aluminum-4Vanadium Components for Surgical Implant Applications”

- ASTM F2989-13: “Standard Specification for Metal Injection Molded Unalloyed Titanium Components for Surgical Implant Applications”

In addition, our Ti MIM material has been tested for biocompatibility, toxicity, geometric repeatability, mechanical and chemical material characteristics, surface finish, density, microstructure, fatigue life, stress corrosion cracking, weldability and more.

Our Ti Powder Metallurgy manufacturing processes are proven with validated equipment and processes for the medical industry.

The first Titanium MIM parts had approval to implant in Europe Asia and South America in 2006. In 2012 the first Titanium MIM parts made by Element22 received FDA approval to implant in USA.