Titanium

Titanium is one of the strongest and most durable metals on earth. It is the chemical element with the symbol Ti and the atomic number 22 which form our name: Element22.

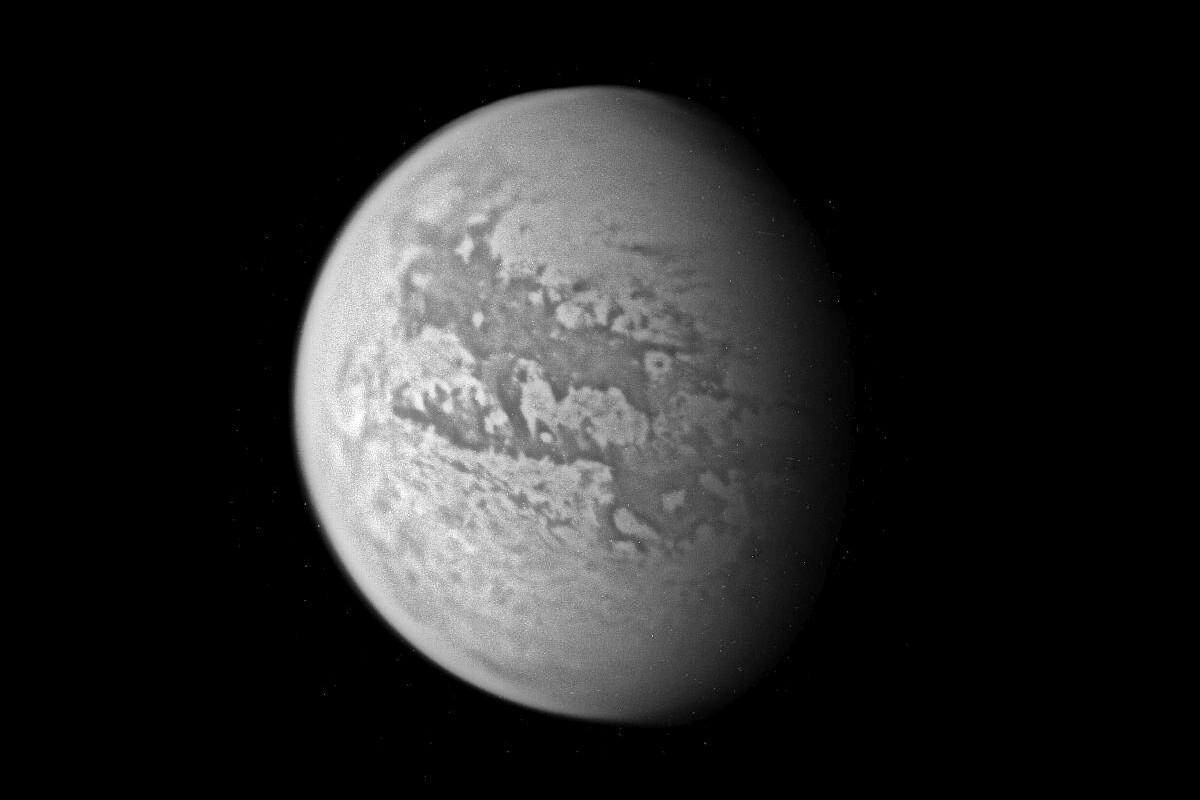

Named after the Titans in Greek mythology -the famous giants in human form- the metal Titanium stands for incredible properties. The biggest moon of planet Saturn is called "Titan" and looks very similar to the powder we use.

Titanium is the ninth most abundant element in the earth’s crust and therefore readily available. Due to its properties, traditional manufacturing methods developed in the first industrial revolution make it difficult to process.

New Powder Metallurgy based manufacturing methods like

Metal Injection Molding (MIM) or 3D Printing (3DP)

are excellent candidates for processing Titanium, but require Know-How and specialized equipment.

In metal 3DP about 50% of the products manufactured are made of Titanium due to its excellent material properties. The extremely fast expanding 3DP and Powder Metallurgy industry has generated a new industry sector for manufacturing spherical Titanium powder with a rapidly growing number of providers and capacity.

Titanium is one of the strongest and lightweight metals on earth. It has the best strength to weight ratio, the so-called specific strength of all materials readily available.

It combines superior material properties: it is strong, lightweight, corrosion resistant, biocompatible and has an excellent fatigue life. That combination makes it an ideal choice for many demanding applications.

It can be alloyed with several elements to create a specialized material. The most common Titanium alloy is Ti6Al4V, also known as “Grade 5”. It combines a high strength with good ductility while having an excellent fatigue strength.