Aviation

Titanium is an excellent material choice for the aerospace industry due to its properties.

In combination with other material like carbon-fiber reinforced polymers, it has started to replace Aluminum parts in aircraft manufacturing over the recent years. This is due to its ability to resist heat and corrosion when it comes in contact with carbon-fiber reinforced polymers (CFRPs). The aerospace industry is evolving and new opportunities like drones and Personal Air Vehicles (PAV) are developing with rapid speed.

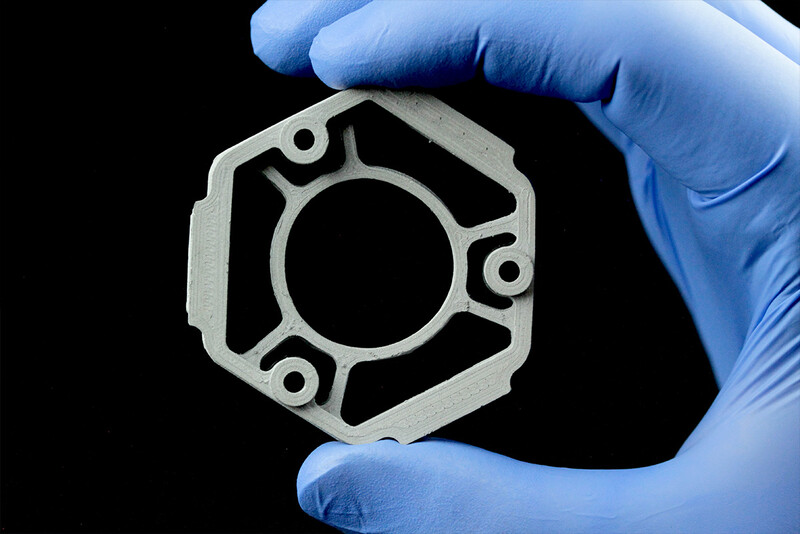

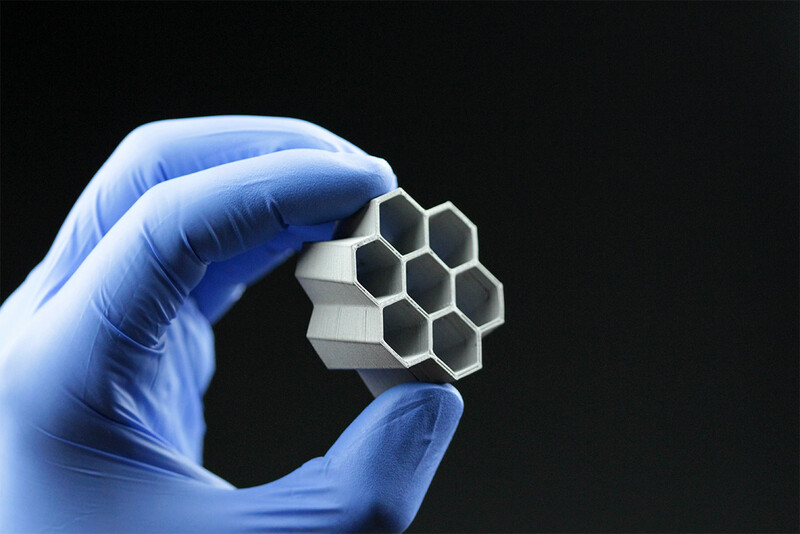

Titanium is being used in many aerospace applications like fastening elements, airframes, landing gears and others. Powder Metallurgy shaping processes like MIM and 3DP offer a great material efficiency and allowing reducing the buy to fly ratio significantly. It is a resource friendly production option and helps reduce the carbon footprint.

Element 22 has fully validated process chains and is certified to EN/ AS 9100.