Renewable energy

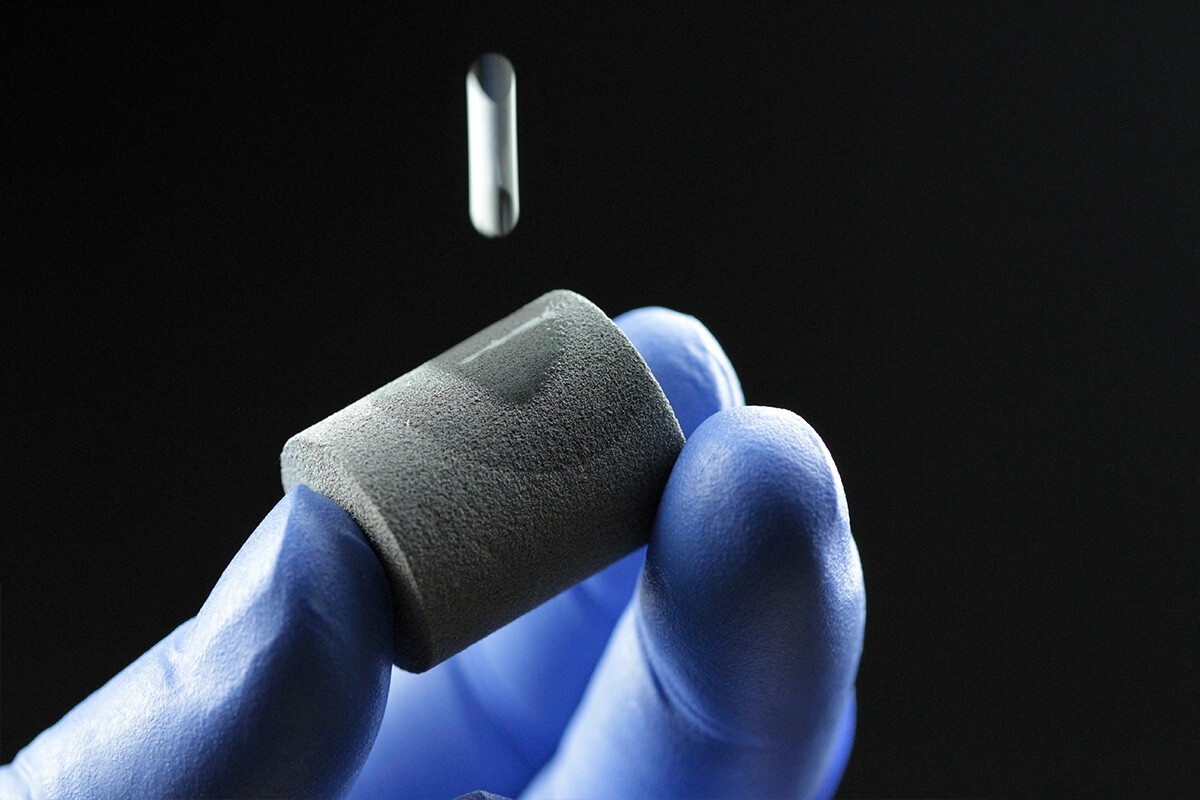

Titanium is known as one of the most lightweight, strong and corrosion resistant materials and is therefore perfectly suited for Hydrogen Electrolyzer.

To reduce carbon dioxide emissions and reduce the dependency on fossil fuels, an increased usage of renewable energy sources is necessary. Renewable power generation is volatile and mainly dependent on wind and sunshine. In order to use renewable power, reliable and effective storage options are necessary. Hydrogen is an excellent and scalable solution to store and transport massive amounts of energy. Hydrogen is generated by electrolyzing water, whereby Titanium is needed. During the electrolyzing process free single oxygen radicals are created, which Titanium can resist better than other material available. To increase the use of renewable energy sources, Hydrogen Electrolyzers are needed in industrial Gigawatts scale projects.

Manufacturing the Electrolyzer parts with powder based technologies increases performance and efficiency. Fewer parts are needed and the material properties are superior: less electrical resistance, higher electrical conductivity, better material transport for water and gas. Creating gradient filter structures and flow optimized design will take the efficiency to the next level.